Principles of precise thickness measurements

Non-contact displacement sensors and systems from Micro-Epsilon enable high precision thickness measurements in a wide variety of applications. Here, a distinction is made between one-sided and a two-sided thickness measurements. With one-sided thickness measurements, the sensor determines the target thickness from one side only. Two-sided thickness measurements are performed using at least one pair of sensors mounted opposite each other in one axis. The most important measurement tasks are described below with the appropriate measurement technology.

One-sided thickness measurement of transparent materials using confocal sensors

The confocal measuring principle enables one-sided thickness measurement of transparent materials such as display glass. This means that only one sensor is required for one measuring point. The confocal chromatic sensors from Micro-Epsilon evaluate up to 6 peaks during the measurement, allowing them to monitor individual layers and gaps.

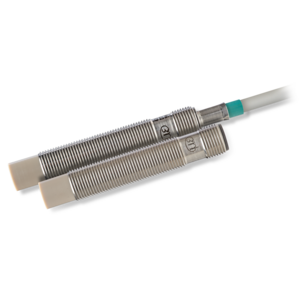

One-sided thickness measurement of plastics and applied adhesives

The combiSENSOR combines an eddy current sensor and a capacitive displacement sensor in one housing and is used for difference thickness measurements of plastic and adhesive. The sensor normally requires a metallic counter electrode (usually a transport roller) as a reference distance. The integrated capacitive sensor detects the distance from the non-conductive plastic or adhesive layer. The controller calculates the thickness of both sensor signals with high accuracy. The combiSENSOR measures even very thin materials.

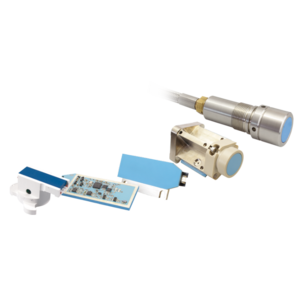

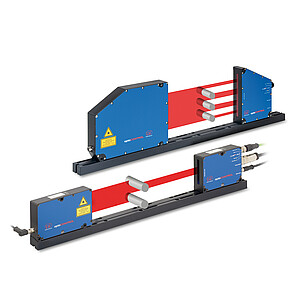

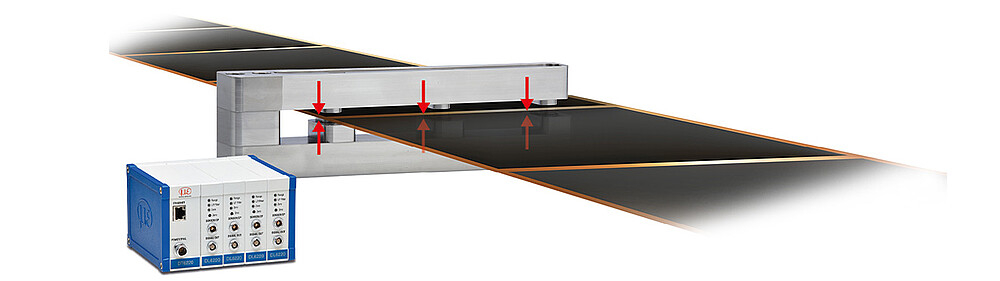

Two-sided thickness measurement using capacitive displacement sensors

Capacitive sensors are used for inline thickness measurements of films, strips and webs. Due to their high temperature stability, these sensors are ideal for dry coating processes. Two capacitive sensors installed opposite to each other perform two-sided thickness measurements of electrically conductive materials. This method is used to measure strip thickness down to the µm range. Each of the two capacitive displacement sensors provides a linear output signal depending on the sensor surface and target surface. As the distance between the two capacitive sensors is known, the thickness of the measuring object can be determined easily. Due to the capacitive measuring principle, the measurement is carried out on the surface without penetrating the object to be measured. The measuring spot of the sensors is larger than those of the optical methods, which averages out any anomalies on the surface.

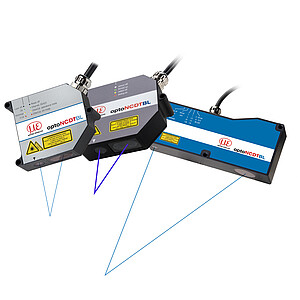

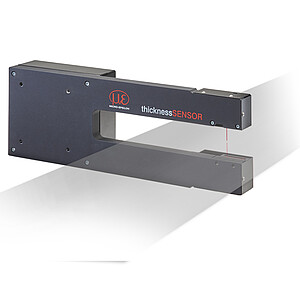

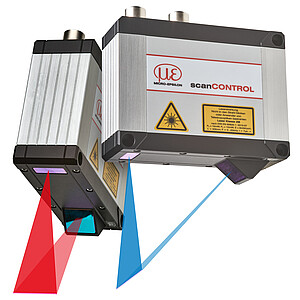

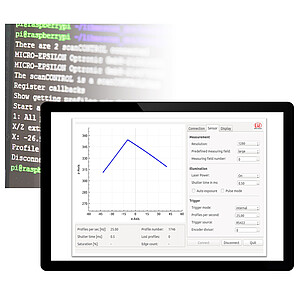

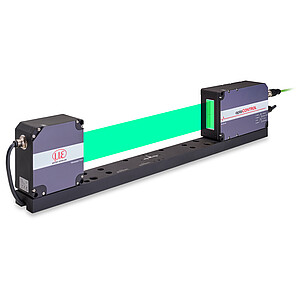

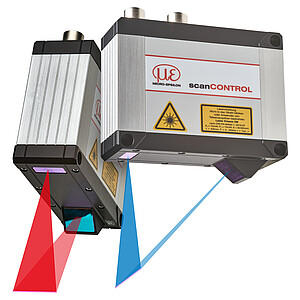

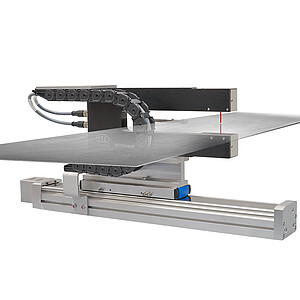

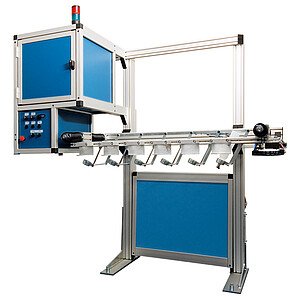

Two-sided thickness measurements using laser sensors

Laser displacement sensors arranged on two sides detect the thickness of different objects according to the differential thickness method. The measurement can be performed on different targets, e.g. plastics, metals, wood and coated glass. The sensors need to be synchronized and precisely aligned to obtain accurate readings. Depending on the measuring range, the sensors can be aligned at a large distance from each other. The thicknessSENSOR is a turnkey sensor system that is ready for thickness measurements.

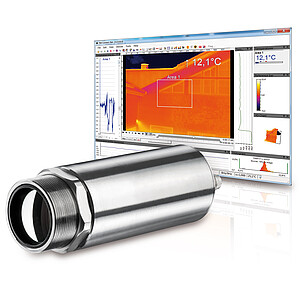

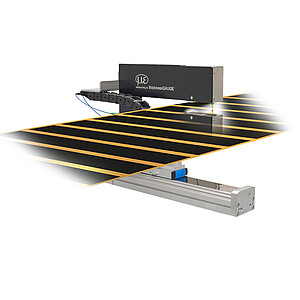

Systems for thickness measurements of black rubber webs

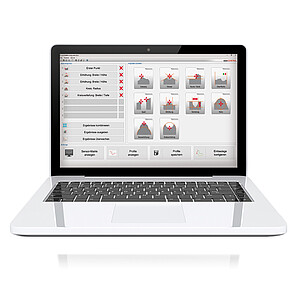

For thickness and profile measurements of tire components and technical rubber, Micro-Epsilon offers industry-specific measuring systems that can be integrated into the production process. These turnkey systems are available with application-specific sensors and come with extensive interface and software packages.

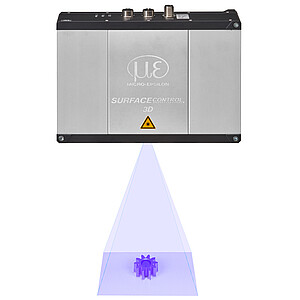

Systems for thickness measurements of plastics

For the thickness measurements of film and thin plastics, Micro-Epsilon offers turnkey measuring systems that are integrated directly into the production line. The systems are designed for inline thickness measurements of plastic film from 10μm and upwards. Depending on the location of use, the measuring systems are equipped with application-specific sensors, interfaces and software packages.

Systems for thickness measurements of metal strip and plate

For thickness monitoring of metal strip and metal plate, measuring systems with application-specific sensors are available. Depending on the model, the systems can be used in cold or hot rolling mills. For traversing bandwidth monitoring, O-frame systems are used, while C-frame systems are used to measure individual tracks. The systems operate independently of alloy and surface properties and so can be used across the entire metal processing industry.